|

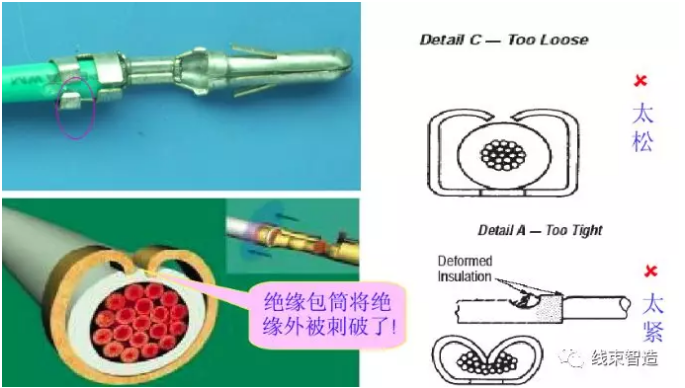

1. Appearance judgment of terminals after riveting: It is acceptable to have an insulation cylinder with a minimum range of 180 degrees that can completely wrap the insulation part of the wire

The insulation barrel riveting on the copper wire of the wire is defective.

It is acceptable to see wire continuity and insulation (not in the 1/2 position) in the insulation inspection window.

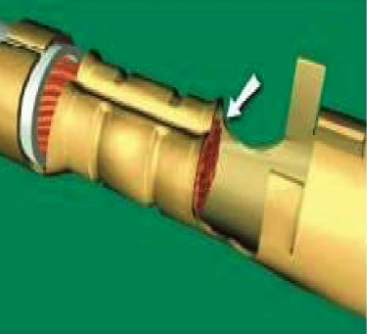

The wire insulation skin is flush with the conductor sheath, but it is acceptable if it does not extend into the conductor sheath. However, at this time, the machine should be stopped and the technician should be notified to adjust the machine. The wire insulation skin that extends into the conductor sheath is rejected. @Dongguan Fulang Connector Manufacturing Co., Ltd The copper wire is riveted into the insulation barrel as a defect If the conductor is flush with the conductor inspection window, it is acceptable, and if it is not visible, it is rejected. If the copper wire of the conductor exceeds the conductor inspection window and affects the insertion, it will be rejected. If the deformation of the terminal is within 4 degrees after riveting, it is acceptable, and if it exceeds 4 degrees, it is rejected. The deformation of the insulation terminal after riveting is acceptable within a range of 5 degrees, otherwise it is considered rejected. The material strip part of the terminal that is not visible after riveting is rejected. If the length of the strip exceeds 2 times the thickness of the terminal material, it shall be rejected. The edge behind the conductor sheath is greater than one time the thickness of the terminal material, which is considered defective. 2. Sequence of terminal inspection During inspection, the front of the terminal should be inspected first and then to the back of the terminal. Usually, the following steps are checked first: front of the terminal → side of the terminal → back of the terminal → side of the terminal → front of the terminal → end of the terminal

The copper wire is riveted into the insulation barrel as a defect If the conductor is flush with the conductor inspection window, it is acceptable, and if it is not visible, it is rejected. If the copper wire of the conductor exceeds the conductor inspection window and affects the insertion, it will be rejected. If the deformation of the terminal is within 4 degrees after riveting, it is acceptable, and if it exceeds 4 degrees, it is rejected. The deformation of the insulation terminal after riveting is acceptable within a range of 5 degrees, otherwise it is considered rejected. The material strip part of the terminal that is not visible after riveting is rejected. If the length of the strip exceeds 2 times the thickness of the terminal material, it shall be rejected. The edge behind the conductor sheath is greater than one time the thickness of the terminal material, which is considered defective. 2. Sequence of terminal inspection During inspection, the front of the terminal should be inspected first and then to the back of the terminal. Usually, the following steps are checked first: front of the terminal → side of the terminal → back of the terminal → side of the terminal → front of the terminal → end of the terminal Terminal side (rotate clockwise to check side one) Check if there are any excessive spikes or deformed terminals. Terminal side (rotate clockwise to check side two) Check whether the terminals are damaged, bent or deformed, and whether the spring clips are deformed. Terminal tip Check whether the terminals are deformed, whether the front horn is deformed, and whether the material strip is too long. Terminal end Check whether the insulation copper riveting is good, whether there are cuts or insulation skin peeling, and whether the material strip is too long. 3. Poor appearance of terminal pressing: Slip one's feet Copper wire length with skin injection and exposed Terminal head deformation The core wire is not riveted in place Deformation at the conductor sheath Crushing, broken copper wire on the inner surface of the wire skin Conductor wrapped without copper wire Over position, exposed length of copper wire The insulation barrel is deformed and the insulation skin is not covered Green core wire injection leather The insulation skin is damaged, and the copper wire is not fully wrapped in the conductor barrel Terminal bent at point A |